- GST No. 07AACCR7265D1ZE

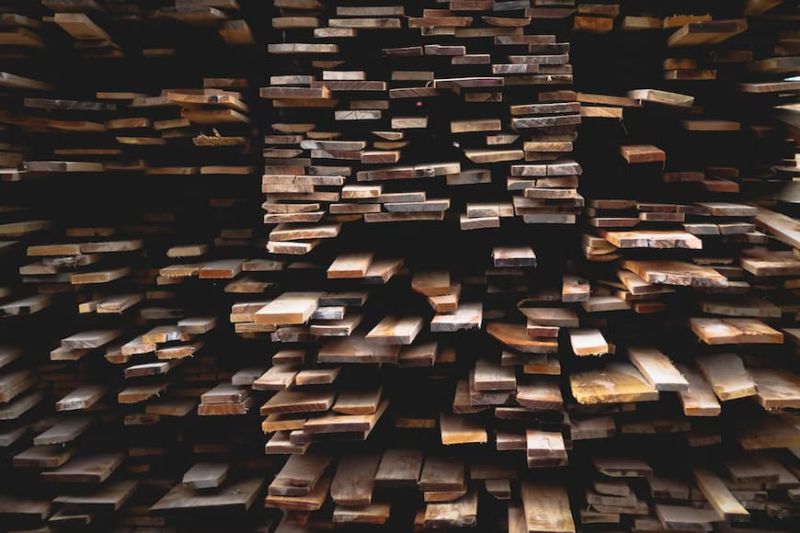

Thermo Treaed Wood

Price : INR 3,500.00 - 4800.00 / Cubic Feet

The Benefits of Thermo-Treated Wood

Thermo-treated wood emerges as an eco-conscious and resilient choice in the realm of lumber. What sets it apart is a process that enhances its durability while reducing its environmental impact. This makes it a preferred choice for a wide range of applications, both outdoors and indoors.

Thermo-treated wood, often used for outdoor decking and siding, gains its strength from a specialized heat treatment process. This treatment not only increases its resistance to decay but also reduces the need for chemical preservatives, making it an environmentally sustainable option. Thermo-treated Pine and Thermo-treated Ash are among the popular species available, each offering unique attributes. Thermo-treated Pine is favored for its affordability and suitability for outdoor projects, while Thermo-treated Ash brings a touch of sophistication and adaptability, making it suitable for both exterior and interior applications. These options within the Thermo-treated wood family provide flexibility and eco-friendliness, ensuring that you can choose the right material for your specific project while minimizing the environmental footprint.

Versatile Thermo-Treated Wood Species

Exploring the world of Thermo-treated wood uncovers a diverse array of options. Thermo-treated Pine stands out for its cost-effectiveness and suitability for outdoor uses such as decking and siding. It's a great choice for those looking to create durable, eco-friendly outdoor spaces. On the other hand, Thermo-treated Ash offers versatility that extends from outdoor projects to indoor applications. Its elegant appearance and resistance to decay make it a valuable choice for both exterior and interior designs. Whether you're revamping your outdoor deck or adding character to your living space, Thermo-treated wood, with its durability and environmental considerations, opens up a world of possibilities for your woodworking projects.

Frequently Asked Questions

What does heat treating do to the wood?

Heat treatment gives wood enhanced endurance which is called thermal treatment of wood. This gradual heating of wood is done up to 410° to 450° Fahrenheit.

What is Thermo Wood?

The Thermo Wood is a new generation of wood material. It gives unique features of weather resistance, water repellency and stability to the wood. It also protects wood without any chemical additives.

For more information : https://en.wikipedia.org/wiki/Thermally_modified_wood

Does he treated wood Road?

Not really, thermal treatment makes molecular changes in board composition which gives protection against whether android. This further expands usage opportunities.

What is modified wood decking?

Decking with the woods boards which are completely modified, all the way through the core, leading to excellent durability and stability without sacrificing the natural qualities of real wood is Modified Wood Decking.

How long does heat treated wood last?

The heat treated wood last quite long. Because wood is as a natural material, it is prone to withering and rotting when ageing. With the heat treatment the natural look and properties of wood are preserved while the withering and rotting are eliminated.

How is Thermo Wood made?

The Thermo Treated meant of wood cycle includes preliminary drying under water saturated conditions. The wood in result offer significantly reduced absorbency. Steam is used to prevent the wood from burning or cracking.

What are the advantages of Thermo Treated Lumber?

-

The lumber has more resistance against mould and rot and through that, species which are normally not suitable for outdoor-uses, can now be taken for outdoor use.

-

The swelling of thermo- treated lumber is reduced.

-

Reduction of the equilibrium humidity content.

-

Due to the darker colour of the thermo-treated wood , European species which are eco-logical acceptable and from PEFC and / or FSC- Certified forests, become an attractive alternative to exotic species.

Are there any disadvantages at Thermo – Treated Lumber?

Depending on the level of Thermo – Treatment (duration/ temprature) the lumber is less flexible and becomes more brittle. Due to that Thermo – Treated wood products should not be taken for constructional load bearing purposes.

What else must be considered?

The surfaces of Thermo- Treated Lumbers lighten up in sunlight getting a grey colour sooner than natural wood. If a customer would like to get grey coloured faces (i.e. at wall-claddings), no further surface-treatments are necessary. Wood-surfaces normally become a really homogenous grey colour.

For the original colour of the thermo-wood to be kept for as long as possible, different kinds of surface-treatments with UV – blockers are needed and must be repeated as necessary. As wood is a natural product, the process of greying or lightening up can only be reduced, it cannot be completely stopped, which is also the case for species which are used in the natural state without thermo treatment.

Thermo-Treated Lumbers and their Purpose

How does Thermo-treatments work?

Thermo – treatment is a procedure, which treats the lumber with heat. Before thermo treatment the lumber must be carefully Kiln- dried to a humidity of 6 – 8%.

After that the lumber is placed into a chamber especially developed for that treatment. In this chamber the lumber will be treated for a specific time and at a specific temprature. The temprature will be increased up to a range between about 190 and 220 degree celcius.

The process of thermo- treatment is achieved purely by giving heat and steam into the chamber, nothing else, which means no chemicals are used in the process. At our mill the heat and steam used in the kilning and thermo treatment process are a by- product of our own wood waste burning electricity generating power plant, meaning that it is a genuinely ” Green” process.

What happen during these procedure?

During this procedure the structure of the wood changes, meaning a reduction in the content of sugar molecules. furthermore the natural colour of the wood becomes darker through the treatment, through and through – not at the surfaces only!

These changes depend on the duration and temprature of the thermo-treatment procedure. The longer the duration and the higher the temperature the more are the changes to the wood.

Specifications

| Color | Dark Brown |

| Country of Origin | India |

| Feature | Durable And Strong |

| Use for | Cutting |

| Material | Wood |

Contact Us

RDBL Enterprises Pvt Ltd

A-5 Whs, Kirti Nagar, Kirti Nagar, Delhi - 110015, India

Call Us : View Mobile Number

Phone : +91-11-41420560, +91-11-41420660